Metal injection molding (MIM) is a manufacturing process that allows for the production of complex-shaped parts with high precision and accuracy. Wholesale Metal Injection Molding Parts has revolutionized the manufacturing industry, particularly for metal parts production. The process involves the mixing of a metal powder with a binder material to form a feedstock that is then injected into a mold. The resulting parts are then debinded and sintered to achieve their final properties.

One of the main advantages of MIM parts is their high precision and accuracy. The process allows for the production of complex-shaped parts with tight tolerances and excellent surface finishes. MIM parts can also be produced in large quantities, making it a cost-effective manufacturing process. Additionally, MIM parts have excellent mechanical properties, including high strength, hardness, and wear resistance, making them suitable for a wide range of applications.

In the automotive industry, MIM parts are used to produce components such as gears, brackets, and fuel injectors. The high strength and wear resistance of MIM parts make them ideal for automotive applications where durability is essential. Additionally, MIM parts can be produced in large quantities, making them suitable for mass production.

In the aerospace industry, MIM parts are used to produce components such as turbine blades, fuel nozzles, and brackets. The high precision and accuracy of MIM parts make them ideal for aerospace applications where tight tolerances and complex geometries are critical. Additionally, MIM parts can be produced with a range of materials, including high-temperature alloys, making them suitable for high-temperature applications.

In the electronics industry, MIM parts are used to produce components such as connectors, terminals, and sensors. The high precision and accuracy of MIM parts make them ideal for electronics applications where tight tolerances and complex geometries are critical. Additionally, MIM parts can be produced with a range of materials, including magnetic and conductive materials, making them suitable for a wide range of electronic applications.

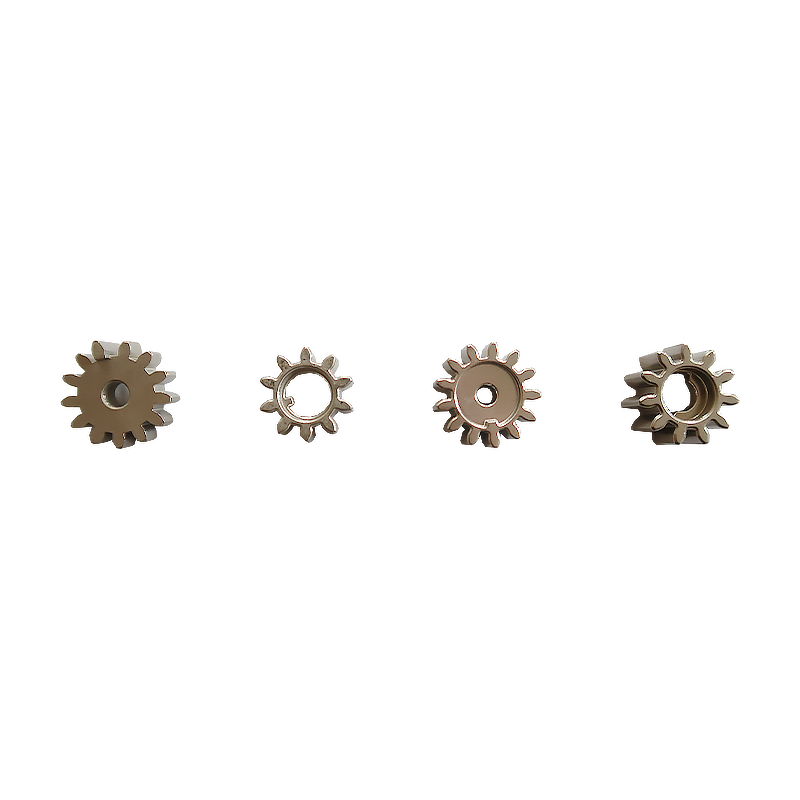

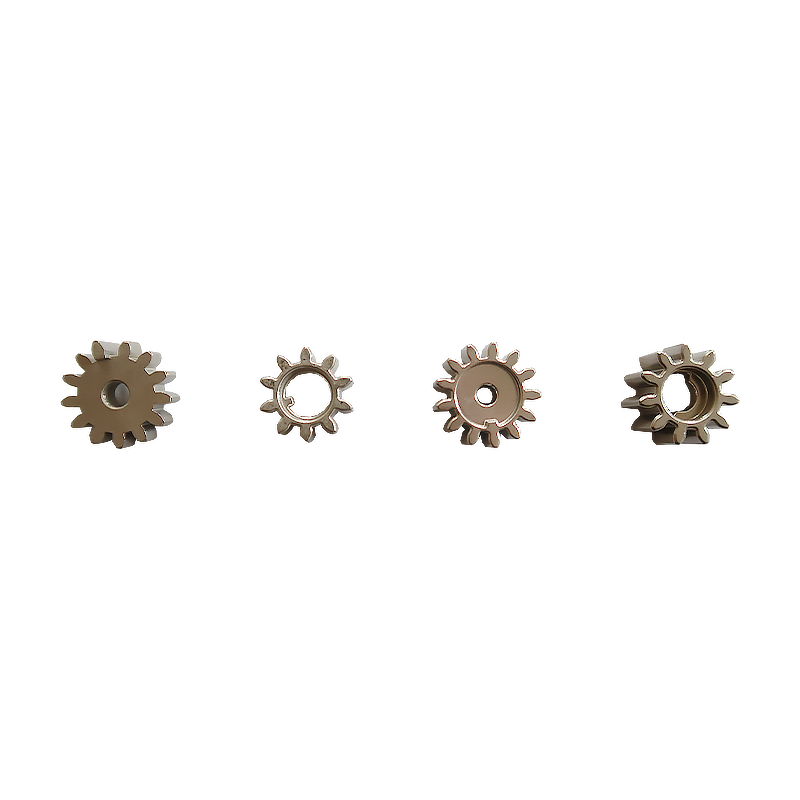

Product Description:Lock gear

Application &Purpose:this part is mainly for lock used for automotive , civil lock and other home appliance precision components .

Material:stainless steel 304,316 Etc .

Main Process:Mixing alloy powder-inection molding-vacuum sintering-sizing(needed)-machining(needed)-polishing(needed)-packing

简体中文

简体中文 English

English