Powder metal parts possess a wide range of properties and characteristics that make them desirable for various applications. Some of the key properties and characteristics of powder metal parts are:

1.High Density: Powder metal parts have a density that can range from 6.5 g/cm³ to 7.5 g/cm³, which is comparable to that of wrought metal parts.

2.Excellent Strength: Powder metal parts can exhibit high tensile, compressive, and yield strengths that are comparable to those of wrought metal parts. This makes them suitable for applications that require high strength and stiffness.

3.Good Wear Resistance: Powder metal parts have excellent wear resistance due to their high density and the ability to be manufactured with various additives such as graphite, molybdenum disulfide, and other solid lubricants.

4.Dimensional Stability: Powder metal parts have good dimensional stability due to their high density and the use of precise die pressing and sintering processes.

5.Complex Geometries: Powder metal parts can be manufactured with complex shapes and geometries that are difficult or impossible to produce using traditional metal forming processes.

6.Good Corrosion Resistance: Powder metal parts can be manufactured with various alloys and additives that provide good corrosion resistance, making them suitable for applications in harsh environments.

7.Cost-Effective: Powder metal parts can be manufactured in large quantities at a relatively low cost, making them a cost-effective solution for various applications.

The powder metal parts offer a unique combination of properties and characteristics that make them an attractive option for a wide range of applications across wholesale Powder metal parts Factory.

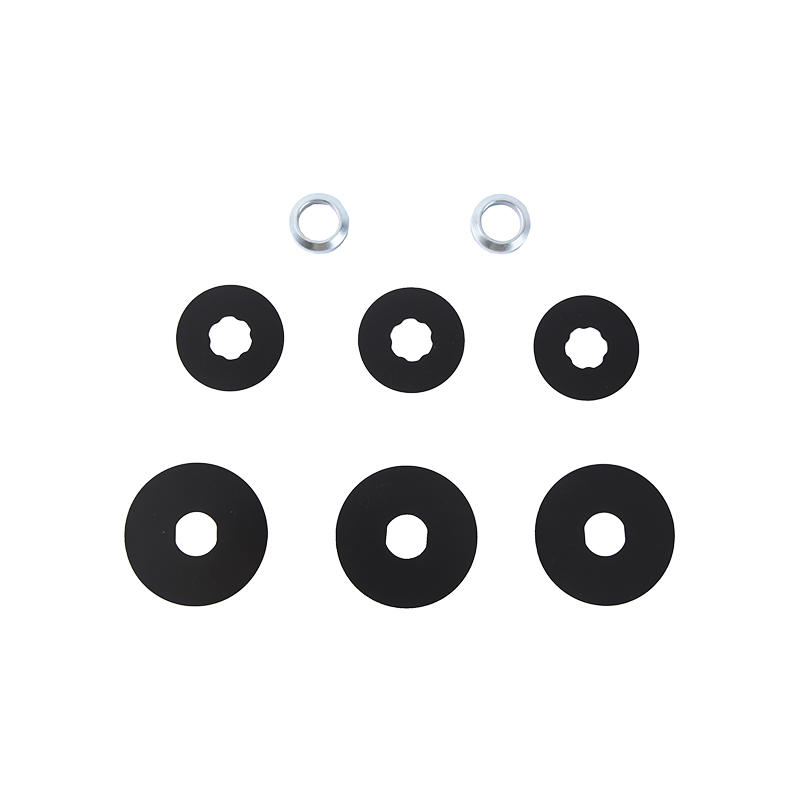

Product Description:tensioner parts -end plate for pivot tube with thread

Application &Purpose:this plate is assembled for the accessory tensioner &idle pulley for the engine belt for crankshafts; with thread punching into the pivot tube, with Powder metal sintering process cost is much improved and efficiency is very high with high capacity requirement of thread .with E-coating surface treatment keep more longer anti-rust and good appearance for aftermarket

Material:Iron powder sintered FC-0208-40(Copper added alloy)Customerized material

Main Process:Mixing iron alloy powder-forming-sintering-steam treatment-E coating -packing

简体中文

简体中文 English

English