Powder metal parts find a wide range of applications across various industries due to their unique properties, cost-effectiveness, and versatility. Some typical applications include:

1.Automotive Industry:

Gears: Powder metal gears are used in transmissions and gearboxes for their excellent wear resistance and quiet operation.

Bearings: Powder metal bearings are employed in engines and suspensions due to their self-lubricating properties and high load-bearing capacity.

Sprockets: Powder metal sprockets find use in chain-driven systems for motorcycles and bicycles.

Engine Parts: Critical engine components like connecting rods, crankshafts, and camshafts are often made using powder metallurgy to achieve high strength and dimensional accuracy.

Valve Guides: Powder metal valve guides offer good wear resistance and precise valve control.

2.Aerospace Industry:

Aircraft Engine Parts: Powder metal parts are used in turbine components, compressor parts, and other high-stress applications in jet engines.

Landing Gear Parts: Components like landing gear bushings and bearings benefit from powder metallurgy's strength and weight advantages.

Structural Components: Powder metal parts are utilized in aircraft structures where lightweight materials with high strength are required.

3.Medical Devices:

Dental Implants: Powder metal dental implants are biocompatible and provide good mechanical properties for long-lasting dental restorations.

Orthopedic Implants: Powder metal parts are used in joint replacements, bone plates, and screws due to their strength and compatibility with the human body.

Surgical Instruments: Scalpel blades, forceps, and other surgical instruments often incorporate powder metal materials for precision and durability.

4.Power Tools and Equipment:

Gears: Powder metal gears are common in power tool applications to handle high torque loads.

Bushings: Power tool bushings benefit from the self-lubricating properties of powder metal materials.

5.Electronics and Electrical Industry:

Electrical Contacts: Powder metal contacts are used in switches and connectors due to their high electrical conductivity.

Connectors: Powder metal connectors provide durability and reliability in electrical systems.

Magnetic Components: Powder metal is employed in magnetic cores for transformers and inductors.

6.Industrial Machinery:

Hydraulic Components: Powder metal parts are used in hydraulic valves and pistons for their wear resistance and tight tolerances.

Couplings: Powder metal couplings are utilized in machinery to transmit torque efficiently.

7.Hardware and Hand Tools:

Wrenches: Powder metal wrenches offer strength and durability for heavy-duty applications.

Screwdrivers: Precision powder metal parts are used in screwdriver tips for improved performance.

Cutting Tools: High-speed steel cutting tools often contain powder metal materials for increased wear resistance.

8.Sporting Goods:

Golf Club Heads: Powder metal materials are used to create lightweight yet strong golf club heads.

Bicycle Components: Powder metal parts in bicycle components contribute to better performance and reduced weight.

9.Consumer Goods:

Household Appliances: Powder metal components are used in various household appliances for their cost-effectiveness and precise tolerances.

Locks: Precision powder metal parts are employed in lock mechanisms for security and durability.

10.Oil and Gas Industry:

Valves: Powder metal valve components are used in critical applications to withstand harsh environments and corrosive fluids.

Pumps: Powder metal pump parts provide wear resistance and dimensional stability.

11.Renewable Energy:

Wind Turbine Components: Powder metal parts are employed in wind turbine gearboxes and generator systems for improved efficiency and durability.

Solar Power Systems: Powder metallurgy is used in solar cell components for their electrical properties and thermal stability.

12.Computer Hardware:

Heat Sinks: Powder metal heat sinks are utilized to dissipate heat from electronic components efficiently.

Hard Disk Drive Components: Precision powder metal parts are used in hard drives for reliable data storage.

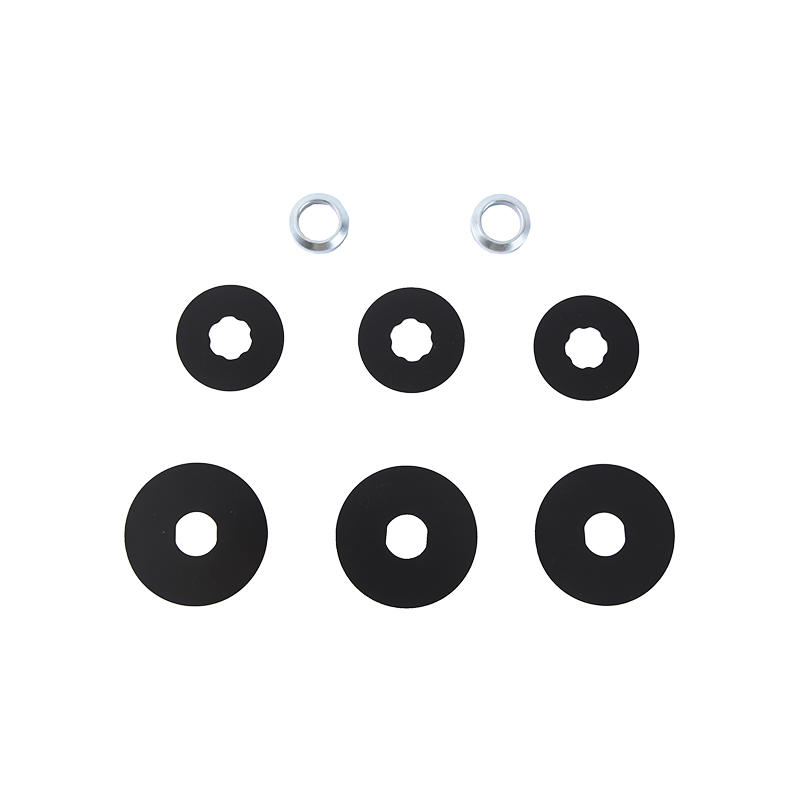

Material: Iron powder sintered FC-0208-40(Copper added alloy)Customerized material

Main Process: Mixing iron alloy powder-forming-sintering-steam treatment-E coating -packing

简体中文

简体中文 English

English