Powder metal pulleys are a type of pulley that is manufactured using powdered metal technology. This method involves mixing metal powders with binders and then compressing them into the desired shape under high pressure. The resulting product is a pulley that is strong, durable, and able to withstand heavy loads. In this article, we will discuss the benefits and applications of powder metal pulley wholesale Powder Metal Pulley Manufacturers.

Cost-Effective: One of the main benefits of powder metal pulley manufacturing is its cost-effectiveness. The process involves minimal waste and requires less energy than traditional manufacturing methods, which makes it a more affordable option for producing high-quality pulleys.

Customizability: Powder metal pulley manufacturing allows for a high degree of customization. Pulleys can be manufactured in a variety of shapes and sizes, making them suitable for a wide range of applications.

Strength and Durability: Powder metal pulleys are incredibly strong and durable. They can withstand heavy loads and extreme temperatures without becoming deformed or damaged.

Reduced Friction: Powder metal pulleys have a smoother surface finish than traditional pulleys, which reduces friction and wear. This results in longer lifespan of the pulleys and less maintenance.

Automotive Industry: Powder metal pulleys are widely used in the automotive industry. They are used in engine components such as water pumps, power steering pumps, and crankshaft pulleys.

Industrial Machinery: Powder metal pulleys are also used in a variety of industrial machinery applications. They are used in conveyor systems, printing presses, and machine tools.

Power Transmission: Powder metal pulleys are commonly used in power transmission applications. They are used in belt drives, chain drives, and other power transmission systems.

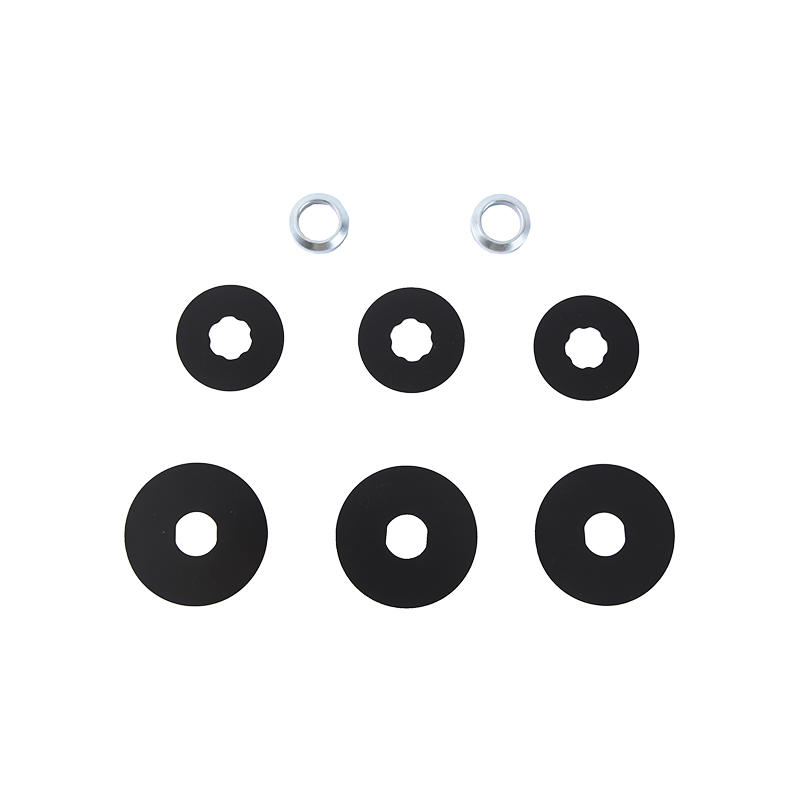

Product Description:Automotive engine power transmission system parts(pulley)

Application &Purpose:this pulley is assembled for accessory tensioner &idler pulley for engine belt for crankshafts ;Powder metal sintering process cost is better than the CNC machining process and molding process is very high efficiency for capacity ;density can achieve 6.8 compared with carbon steel

Material:Iron powder sintered FC-0208-40(Copper added alloy)Customerized material

Main Process:Mixing iron alloy powder-forming-sintering-steam treatment-CNC Lathe machining-Anti-rust oil spraying-packing

简体中文

简体中文 English

English