Powder metal pulleys are a crucial component in many industrial applications. Wholesale Powder Metal Pulley Factory are used in power transmission, conveyor systems, and other machinery applications.

Material Selection: The first consideration in designing a powder metal pulley is material selection. The choice of material will depend on the specific application of the pulley. Materials commonly used in powder metal pulley manufacturing include iron, copper, and steel.

Geometry: The geometry of the pulley is also an important design consideration. The shape and size of the pulley will determine its load-bearing capacity and its ability to transmit power. Pulleys can be designed in a variety of shapes, including V-belt, flat belt, and timing belt pulleys.

Tolerance and Finish: Tolerance and finish are critical design considerations in powder metal pulley manufacturing. Tolerance refers to the allowable deviation from the intended dimensions of the pulley. A tight tolerance is necessary to ensure proper function and compatibility with other components. The finish of the pulley is also important. A smooth finish will reduce friction and wear, increasing the lifespan of the pulley.

Production Volume: The production volume is another design consideration in powder metal pulley manufacturing. High-volume production requires specialized equipment and processes. Small-scale production may be more suitable for custom designs or specialized applications.

Testing and Quality Control: Testing and quality control are essential in powder metal pulley manufacturing. The finished product must be tested to ensure that it meets.

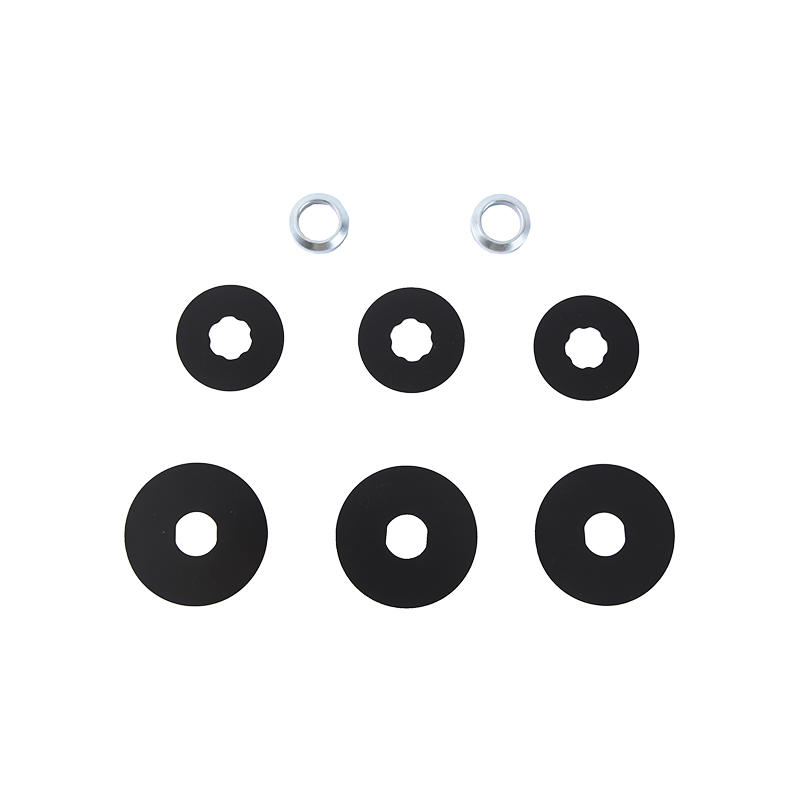

Product Description:Engine tensioner parts( Poly-v grooved pulley)

Application &Purpose:this pulley is assembled for accessory tensioner &idler pulley for Poly-V belt for crankshafts ; this pulley can be applied for heavy tudy vehicles like 7 Liters to 13 liters for different groove

Material:Iron powder sintered FC-0208-40(Copper added alloy)Customerized material

Main Process:Mixing iron alloy powder-forming-sintering-CNC lathe machining-steam treatment-CNC Lathe machining-Anti-rust oil spraying-packing

简体中文

简体中文 English

English